Humanity could also be divided on an excellent many points, however most would agree that it might be very cool to have airplane wings fabricated from shapeshifting steel. The geometry of these fabulous foils impacts just about each side of flight, and making them from steel that may change its form in midair may make your journey smoother, safer, and extra environment friendly.

Shapeshifting wings aren’t new. The Wright brothers flew over the North Carolina sand dunes utilizing a hip brace and wires to warp the Flyer’s cloth-and-wood wings. Fashionable plane obtain the identical outcomes—OK, significantly better outcomes—with mechanically pushed flaps, slats, ailerons, spoilers, elevators, and rudders.

“If you happen to take a look at typical plane expertise, you may have so many transferring elements,” says Othmane Benafan, an engineer at NASA’s Glenn Analysis Middle. These transferring elements are important—they’re how pilots steer, scale back turbulence, take off, land, and principally do all the things else apart from glide aimlessly. However the actuators, cables, motors, lubricant, hydraulic gear, and different bits wanted transfer these elements round take up weight and house—treasured assets on any plane.

The choice is to maneuver these wing elements utilizing shapeshifting metals. Or, as they’re identified to engineers, form reminiscence alloys. “Components constructed from form reminiscence alloys are usually 10 to 20 p.c the scale and weight of a traditional half,” says Jim Mabe, a form reminiscence alloy guru at Boeing. For an trade that spent $133 billion on gasoline final 12 months, something smaller and lighter is thrilling information.

Form reminiscence alloys are basically reversible Shrinky Dinks. When heated to sure temperatures, they shrink, twist, and bend. Cool them off, and so they return to their unique form. Sizzling, chilly, scorching—form reminiscence alloys can cycle backwards and forwards tens of millions of instances with out carrying out. All you want is the flexibility to generate warmth or pull it from another, already spicy scorching a part of the aircraft, just like the engine.

Plane makers, researchers, and authorities companies like NASA can use these metals to do extra than simply scale back gasoline payments. Form reminiscence alloys may also be used so as to add transferring elements to a aircraft, doing issues that may value an excessive amount of in dimension and weight utilizing typical mechanics. For example, quieting a jet engine’s roar. Temperature activated fold-up wings would permit plane carriers to cram extra fighters on deck. This tech may even quell sonic booms, opening the door to the revival of supersonic passenger jets just like the Concorde.

Down Form Reminiscence Lane

Form reminiscence alloys have been developed within the aerospace subject, although not for flight, per se. In 1959, on the Naval Ordnance1 Laboratory, a researcher named William Buehler was growing supplies for intercontinental ballistic missile nostril cones that might endure the acute temperatures and pressures of doing missile stuff like flying to the sting of house, then reentering the environment. Buehler got here up with an alloy of nickel and titanium that was not solely sturdy and fatigue resistant but additionally tremendous malleable at excessive temperatures. He found the alloy’s most shocking characteristic by purposely dropping bars of the stuff on his store flooring and listening to the thuds. (I do know, these are the sorts of tales individuals ought to be telling STEM-shy children.)

The cool bars made a really completely different noise than the bars nonetheless heat from the furnace, indicating to Buehler that the molecules might be in numerous orientations at completely different temperatures—not a standard property of metals. Later one in every of his colleagues held his lighter beneath an accordion-like strip of the alloy. To everybody’s shock it fully unfolded, indicating that the heated molecules have been doing extra than simply increasing in response to the warmth; they have been fully altering the orientation of their bonds. These alloys change section, however not from, say, stable to liquid. They’re altering from one stable section to a different—like ice turning into a distinct sort of ice.

Since that discovery, engineers have gotten reasonably good at coaching the form reminiscence constructions to supply predictable actions at exact temperatures. And so they’ve provide you with all kinds of form reminiscence supplies—even some plastics. Nevertheless, Buehler’s unique form reminiscence alloy of nickel and titanium (known as nitinol) continues to be fairly in style. Many of the supplies innovation lately is making the alloy extra fatigue resistant and tweaking the nickel to titanium ratio to higher management the alloy’s vary of temperature response.

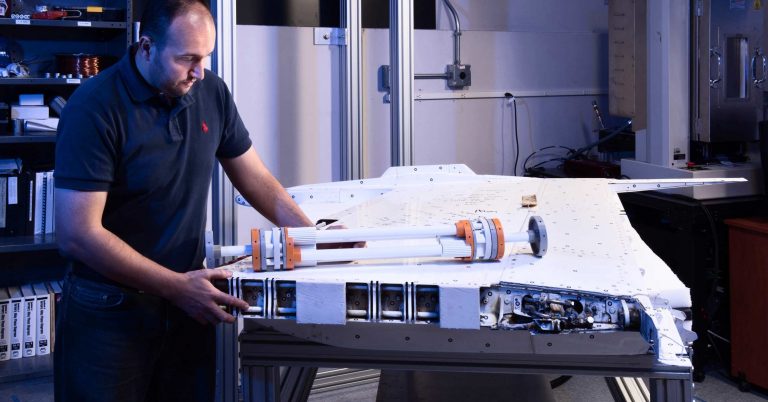

This prototype wing makes use of form reminiscence alloys to alter the wing camber, or relative curve between the wing’s high and backside.

Darren Hartl/Texas A&M

For instance, Benafan makes lengthy, hole nitinol tubes, which he makes use of to interchange the hinges for numerous movable wing elements. He’s testing his tubes on winglets, these upturned bits you see on the finish of many aircraft wings. Ultimately Benafan says, these actuators ought to be capable to transfer these 300-pound sections of wing up or down 180 levels, giving pilots one other instrument to remain steady when turbulence hits. In October Benafan began putting in his form reminiscence tubes inside a hollowed out F/A-18 fighter jet wing, a part of longer-term assessments on how nitinol-powered wings carry out in numerous flight circumstances.

The probabilities transcend the wings. A number of years again Jim Mabe and his Boeing colleagues invented a system to cut back turbine engine noise. Referred to as the variable geometry chevron, it was basically an enormous donut of extra fairing that match across the outer exhaust of a turbine. The aft finish of that fairing zig-zagged—consider the V sample on Charlie Brown’s shirt. Every V got here bolted with thick strips of form reminiscence alloy. When heated, the form reminiscence alloy would bend, and the information of these Vs would dip into the exhaust stream, including simply the correct amount of turbulence to the new air to cut back noise. “The extra you heated the form reminiscence alloy, the extra it might bend, so we may put extra of an angle within the V once we have been in numerous air circumstances,” says Mabe.

Noise is a very vexing aviation downside, particularly for supersonic flight. Regardless of what you’ve heard from Kenny Loggins, most journeys to the hazard zone contain little MiG dodging and plenty of paying for expensive noise violations known as in by the curmudgeons residing beneath your flight path. “Plane in supersonic flight expertise shockwaves all alongside their surfaces,” says Darren Hartl, an aerospace engineer at Texas A&M College. These start on the nostril, and occur once more at each discontinuous floor of the plane the place air comes collectively sharply. These quite a few shockwaves are separate at first, however as they head in direction of the bottom they coalesce. The mixed vitality of all these shockwaves is the way you get the growth.

Plane engineers attempt to design supersonic planes to reduce the growth, however shock waves behave otherwise relying on variables like temperature, humidity, and barometric strain, so there’s no one-shape-silences-all answer. Form reminiscence alloys would permit engineers to design a aircraft with a profile that modified in response to those variables, including just a few additional milliseconds between the shockwaves. “Then you aren’t getting a growth, you simply get just a few comfortable little bumps,” Hartl says.

Sure, typical motors may do the identical work, however they’re simply too cumbersome to take the time worthwhile. “The one daring factor to recollect about form reminiscence alloys is that they have the very best work density per quantity of any actuator,” Hartl says. Nothing else packs extra energy per pound.

Sizzling and Chilly

So what’s holding these miracle supplies again from revolutionizing aerospace or reviving the Concorde? You guessed it: Authorities conspiracy.

Juuuust kidding. It’s your outdated pal forms. The Federal Aviation Administration tightly governs how planes are constructed—thus aviation’s close to impeccable security file, thus a really gradual charge of change. Till not too long ago, the FAA didn’t actually have a certification commonplace for evaluating form reminiscence alloys. However just a few years in the past, Mabe and Hartl organized a bunch of form reminiscence materials lovers from NASA, the army, academia, and trade. The usual they developed, which outlines testing standards for each conceivable side of form reminiscence alloys, was solely accepted this 12 months.

Technical challenges stay, after all. The key one is temperature. Form reminiscence alloys change section in comparatively restrained ranges, and planes don’t do restraint. “They go from -50˚ C at cruising altitude to upwards of 40˚ C on the bottom,” says Hartl. (That’s roughly -58 to 104 Fahrenheit.) So he, and lots of others, are engaged on methods to maintain these metals at simply the best temperature, it doesn’t matter what’s happening exterior.

One other temperature-related problem is controlling how lengthy it takes for form reminiscence alloys to warmth and funky. Take into consideration the time it takes to warmth up or settle down your steel pots and pans. “That ought to offer you some instinct how troublesome this downside is to unravel,” Hartl says. Except engineers work out some finish run round these thermodynamics, form reminiscence alloys received’t be be used for main management techniques—those pilots depend on to have instantaneous suggestions throughout advanced flight ops like takeoff and touchdown.

Nonetheless, that leaves loads of purposes for noise discount, tuning wing form in flight on account of air circumstances, decreasing drag, and different secondary controls. Hartl and different specialists imagine the primary form reminiscence alloy controls will cross via the FAA’s compliance rules and onto actual world planes inside a decade. And positive, these things may by no means result in plane that rework into robots and battle over the destiny of humankind. However then once more, humanity is already dealing with loads of nonrobot challenges, so simply be proud of lighter, smaller flaps, OK?

Aviation Advances

1 No, we did not by chance lose an ‘i’ between the ‘d’ and the ‘n’. Per language site Grammarist: “Though ordinance and ordnance now share no definitions, they each come from the Center English ordinaunce, which means to set so as. A 3rd phrase, ordonnance, which nonetheless seems sometimes [sic], started as a variant of ordinance however has since taken a which means of its personal—particularly, the association of elements in a constructing, image, or literary work.” Although some army historians may argue that the Navy’s mid-century R&D efforts have been within the service of setting sure issues to order, the right spelling of the Naval Ordnance Laboratory implies they have been merely constructing issues that go growth.