As FormNext quick approaches, the 3D printer releases, and teasers are coming thick and quick. Today, Prusa Research has introduced the Prusa Core One L, a bigger model of the excellent Prusa Core One that I reviewed again in January.

I used to be fortunate sufficient to attend the announcement within the Prague earlier within the month and to spend a while with the machine and the opposite launches that have been introduced on the occasion.

You can pre-order the Prusa Core One L by clicking here and utilizing the code TechSwitch.

Core features of the new Prusa CORE ONE L

3D printing is now fully integrated with many areas of manufacturing and business, from the foundations of iterative design and prototyping through to small-scale production runs.

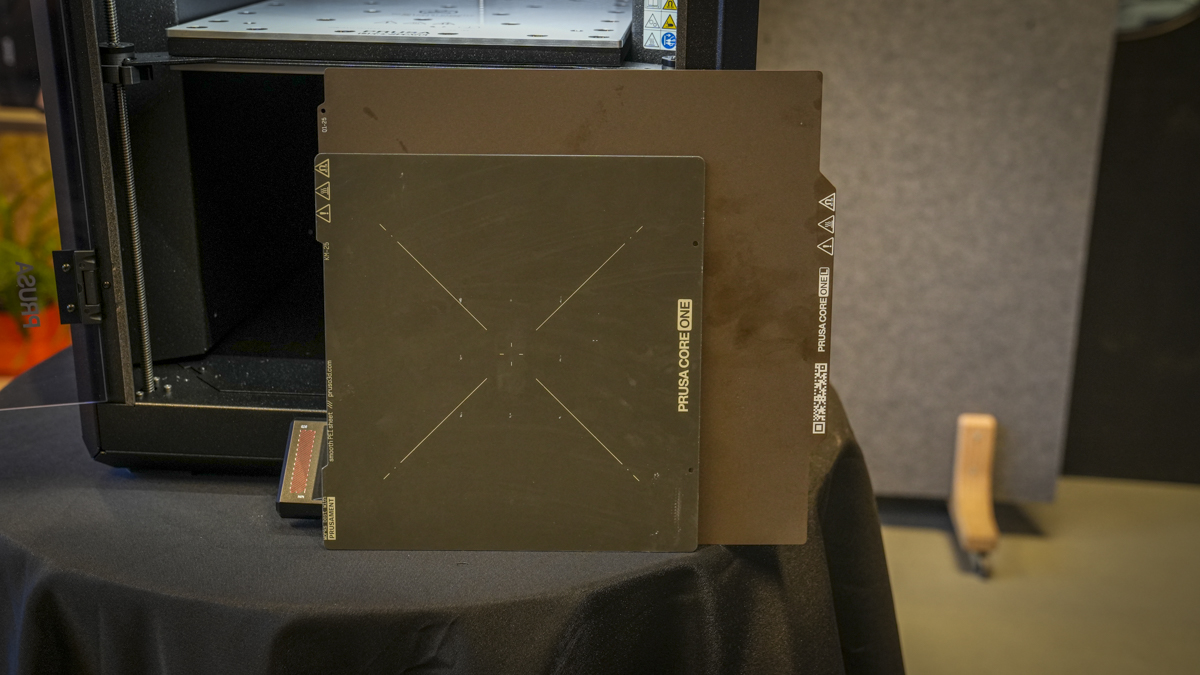

With this comes an industry need for larger volume printers, and the CORE ONE L upscales the print volume by 10% with a 300 x 300 x 330 mm print area within the fully enclosed environment.

The shift from open frame to closed has also meant an expansion in the type of materials that can be used within the machine, and a new AC convection heatbed enables better printing with advanced materials such as PETG, Nylon and ASA.

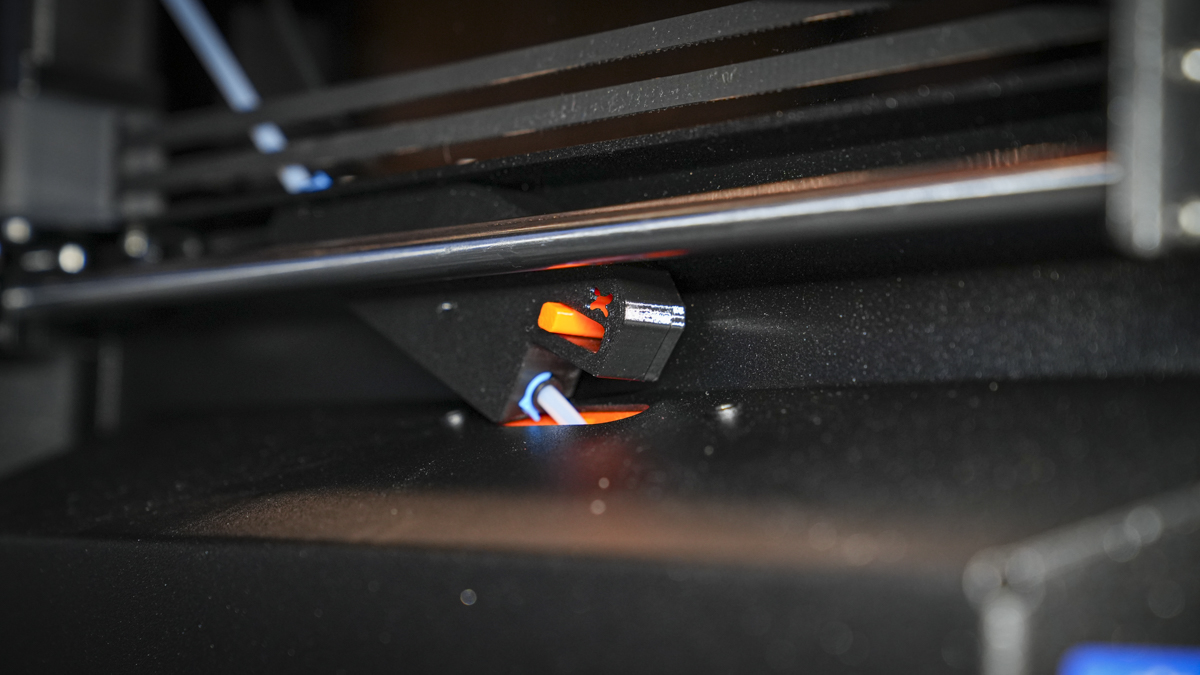

While the heated chamber makes printing with specialist materials possible, the temperature within the machine also needs to be regulated. On the CORE ONE this could be done using the simple manual vent on the top of the machine; now the opening and closing of the vent has been automated.

Surface quality is also a major factor, and PRUSA Research are known for pushing out major advances for their printers through software. Sure enough, with the Prusa Core One L the company has spent a huge amount of time on nerfing VFAs, which takes the already smooth surfaces of the prints to the next level.

Again, as with the Core One, the speed of setup is fast, so if you don’t want to get tangled in the construction of the printer, or for that matter the length calibration process, then with the Core One L that’s all been done for you.

All you need to do is remove it from the packaging, install the filament and switch on. If there are any issues then Prusa Research is one of the only 3D printer companies to offer 24/7 tech support.

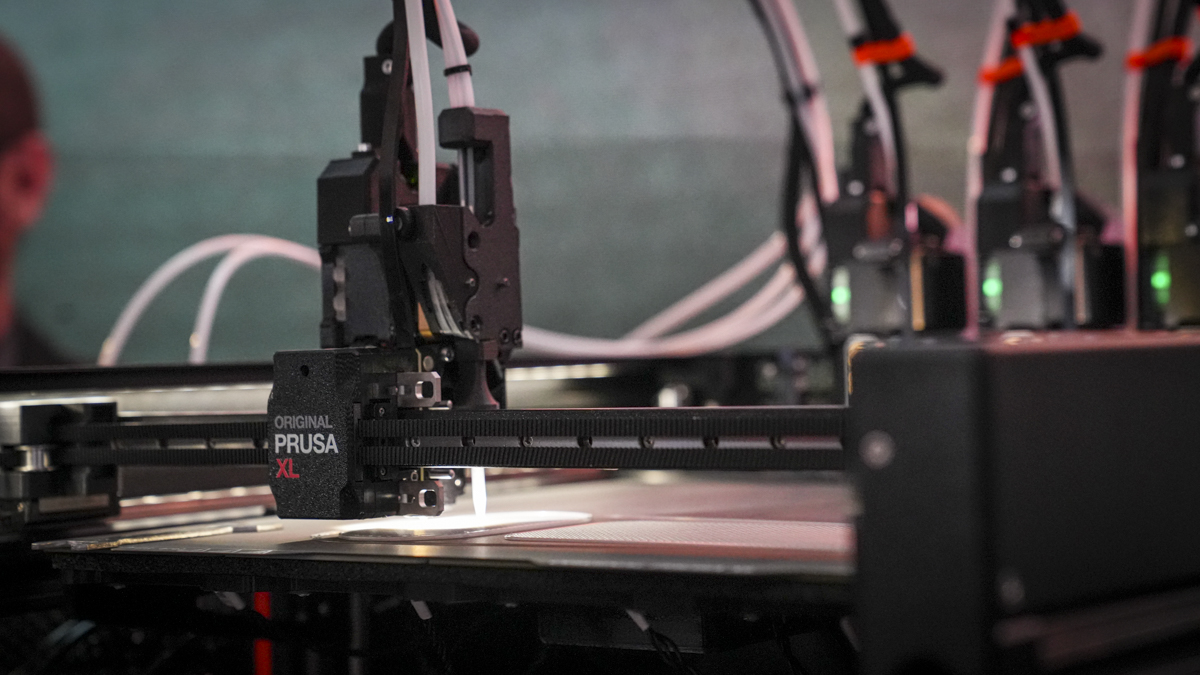

Double the print volume, not the size

Scale with 3D printing is an issue, as to get the meaningful print volume also adds in stability issues, and obviously a larger machine generally means bigger and more weighty. However, PRUSA Research went back to the drawing board and looked for ways to increase the print size without effectively doubling the machine size and weight. The result is a machine that still offers the rigidity through the laser-cut steel profiles from the CORE ONE’s exoskeleton, but then uses aluminium for the side panels and a few other adjustments that have resulted in a machine that is 10% larger and 0.5 kg lighter.

A heated 3D print chamber makes all the difference

Heating the print area is something that has become increasingly common with the shift towards fully enclosed systems, and even more of a focus with the increase in print sizes and the use of specialist materials.

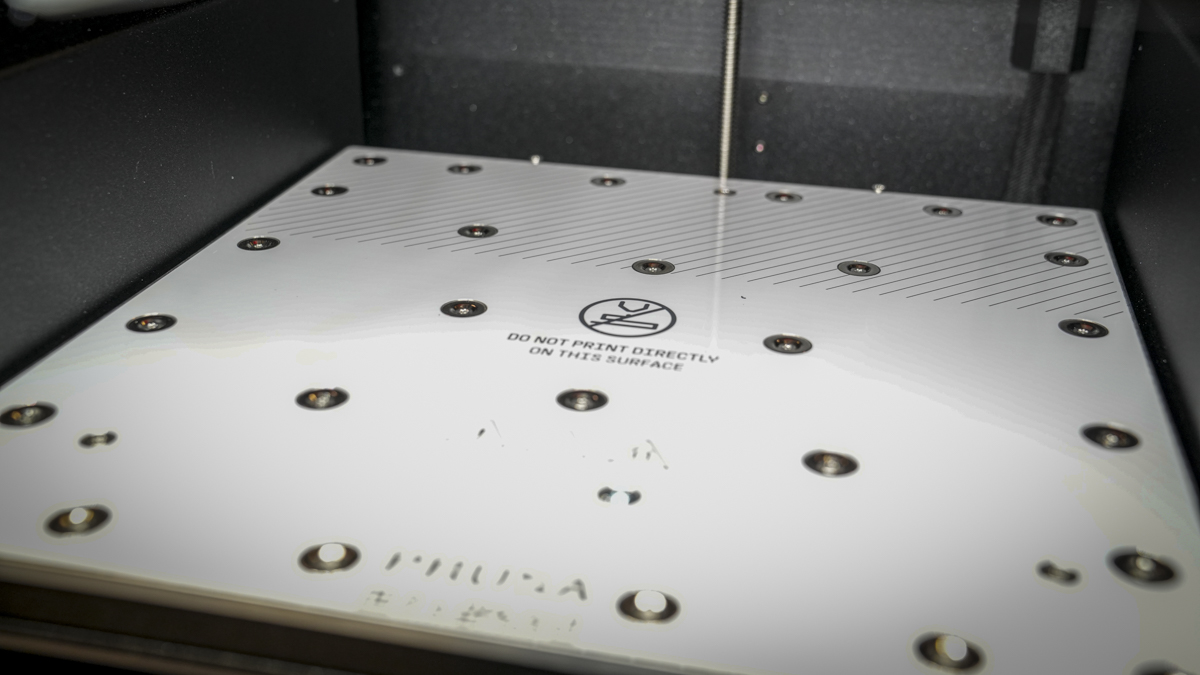

Thermal stability of the print base is also another consideration, and with the Core One L a thick block of aluminium with a dual-loop heat element has been used, which promises to offer a temperature variance of less than 2ºC across the surface. PRUSA Research has also worked hard on the AC convection current to actively heat the chamber, ensuring that it can now reach a maximum of 60ºC when needed.

This heated environment means that many high-performance materials are now far easier and more reliable to print, including ABS, ASA, Nylon and Polycarbonate. When it comes to standard PLA that prints better in a cooler chamber, the vent at the top of the machine now automatically opens, helping to regulate the internal temperature and meaning that there’s no need to leave the door open. If you are using the machine in an office or workshop environment, then there’s also an optional HEPA filtration system that can be used.

Get ready for 3D print production

Let’s face it, if you step into the world of 3D printing there’s a huge choice out there for the consumer. However, when it comes to business, that choice quickly reduces as precise, production-ready parts and dimensional accuracy become the most important factors for purchase.

Prusa Research has tackled this in an interesting way, by essentially refining and keeping things to a degree simple, so on site maintenance and adaptation is possible.

The machine uses a rigid CoreXY kinematics with a 360º cooling extruder that helps to set the filament fast, reducing the need for supports (but not eliminating). Through the PrusaSlicer, organic supports can be added that are far easier to remove than traditional support structures.

While the Core One L remains a single toolhead machine (although you can fit the MMU3 multifilament option), the company has worked on resolving Vertical Fine Artifacts (VFA) with a new feature in PrusaSlicer called “Consistent Surfaces”, which has been designed to enable production-ready prints directly from the print bed.

It’s all about Business

Having tested and used Prusa Research printers for a number of years, the reliability is the key to the company’s success, and for business, this reliability is at the heart of the Prusa Core One L.

Requiring no setup or calibration, anyone can get up and running with the machine in minutes, and the path from files in SolidWorks, Autodesk Fusion, or from STEP files to a physical print from the CORE ONE L has all been streamlined.

If you’re a business looking to learn more about 3D printing, then Prusa Research are well aware that education is key, and here the company is giving access to the comprehensive Prusa Academy online course with every printer. This course delves into the world of workplace use and, for any engineering or product design studio, is an invaluable resource.

Easy maintenance

3D printers by their very nature are complex, and when you look at many of the latest iterations, any thoughts about fixing them yourself are generally out of the question. However, with deep roots in the Open Source community, the Prusa machines are still designed to be maintained by you. Nozzle swaps, which are the most common focus for maintenance, can be swapped in around 30 seconds.

If anything else goes wrong, then everything can be disassembled and rebuilt, meaning that machines, even after thousands of hours of service, can be reconditioned into a good-as-new state.

The Prusa machines are one of the last manufacturers that enable this level of access and onsite repair and maintenance. If you do get stuck or have an issue that you can’t resolve, then there’s 24/7 tech support available in seven languages, staffed by experienced operators.

An open ecosystem

The Prusa printers are part of an open ecosystem that enables you to integrate into the printers and make them part of larger workflows, or sit in secure isolation. PrusaSlicer has become the industry standard, and iterations of the application are now used by most of the industry, and with EasyPrint you can even utilise an online slicer that works across platforms.

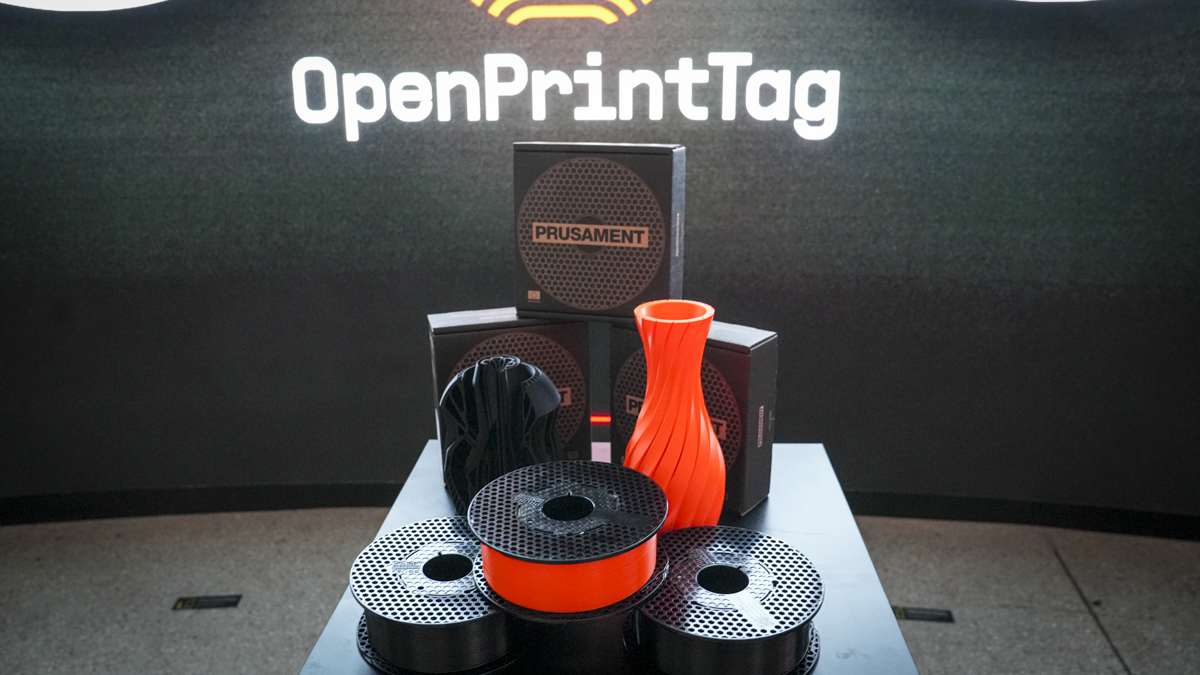

As PrusaSlicer is so integrated with the industry, Prusa Research are also launching the Open Tag Print standard, an open RFID tag in all their new spools that enables the printers to identify the filament type, so that you no longer need to enter the details of the material into the slicer software.

While this technology has been available for over a decade, this is the first time an Open Tag system has been launched, and it could have a dramatic effect on the filament market, with several manufacturers already taking up the format.

More from Prusa Research

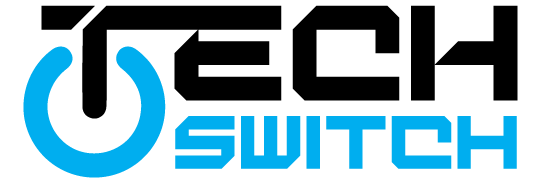

Prusa Signature Oak

Alongside the launch of the CORE ONE L, Prusa Research also announce the Signature Oak, a premium limited-run 3D printer that sees the CORE ONE redesigned with an oak casing. This printer is exceptional, but really one for the core Prusa 3D print enthusiast. Limited to 250 units, it has a price to match and will be an essential for all fans of the Prusa printers.

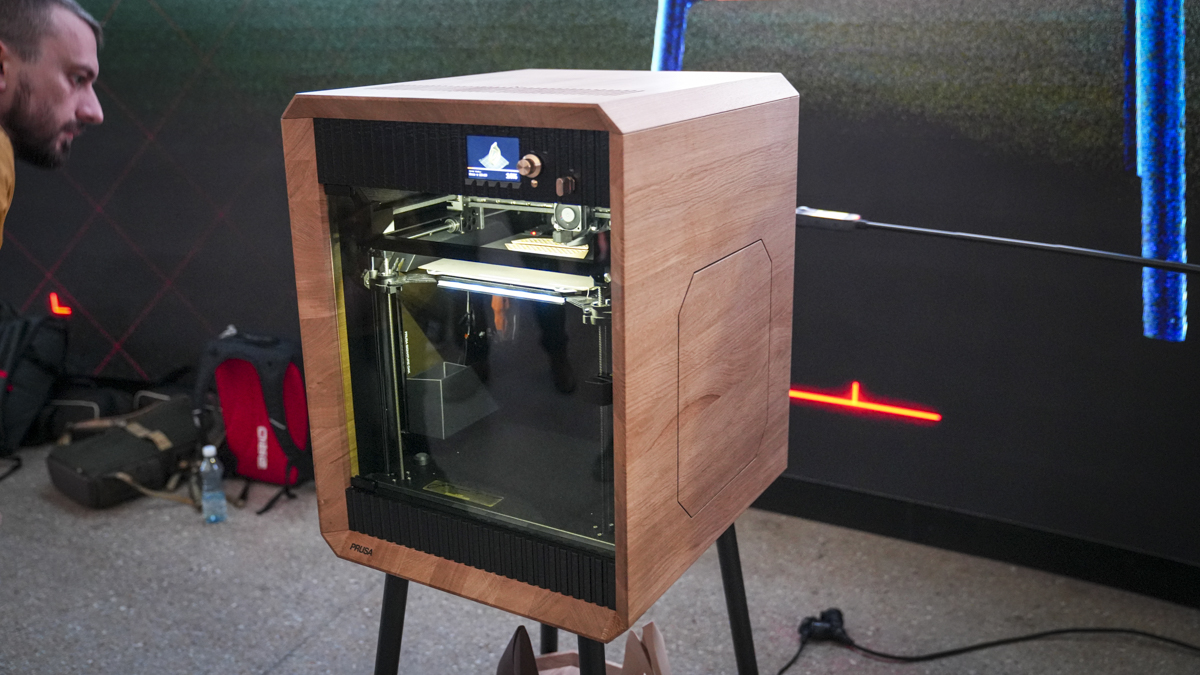

Silicone Tool Head

Developed for the Original Prusa XL, this new software head is sort of in contrast to the rest and can allow the machine to print silicone. The closing launch of the pinnacle is due quickly and I’ll carry extra updates on this as quickly as I’ve them. From the preliminary prints that I’ve seen, it appears to be like to be an fascinating improvement and one thing that will probably be of particular curiosity to trade.

Prusa Research INDX multi-material system

Of course, with the trade headed in direction of multifilament machines, everyone seems to be within the subsequent steps. Following on from a tweet a number of weeks again a couple of cooperation between Prusa Research and Bondtech, it does seem that there will probably be a brand new multi-material INDX answer for the CORE ONE machines that will probably be introduced at FormNext subsequent month. I’ll carry you extra particulars quickly.

If you are interested by pre-ordering a Prusa Core One L you’ll be able to click here and use the code TechSwitch.

The greatest 3D printers for all budgets