Many of us have turn out to be used to constructing our personal PCs, inserting graphics cards and SSDs right into a motherboard. Intel chief govt Pat Gelsinger sees a sea change coming to the chip business the place the chips inside your PC are “assembled” in very a lot the identical method.

This issues. For years, a PC’s processor has been a comparatively easy affair, made by a single firm on a single course of know-how. But one thing occurred in March of this yr that can permit Intel and different firms to combine and match particular items of logic within a single chip, in virtually the precise method PC makers construct PCs.

[ Further reading: The best CPUs for gaming ]

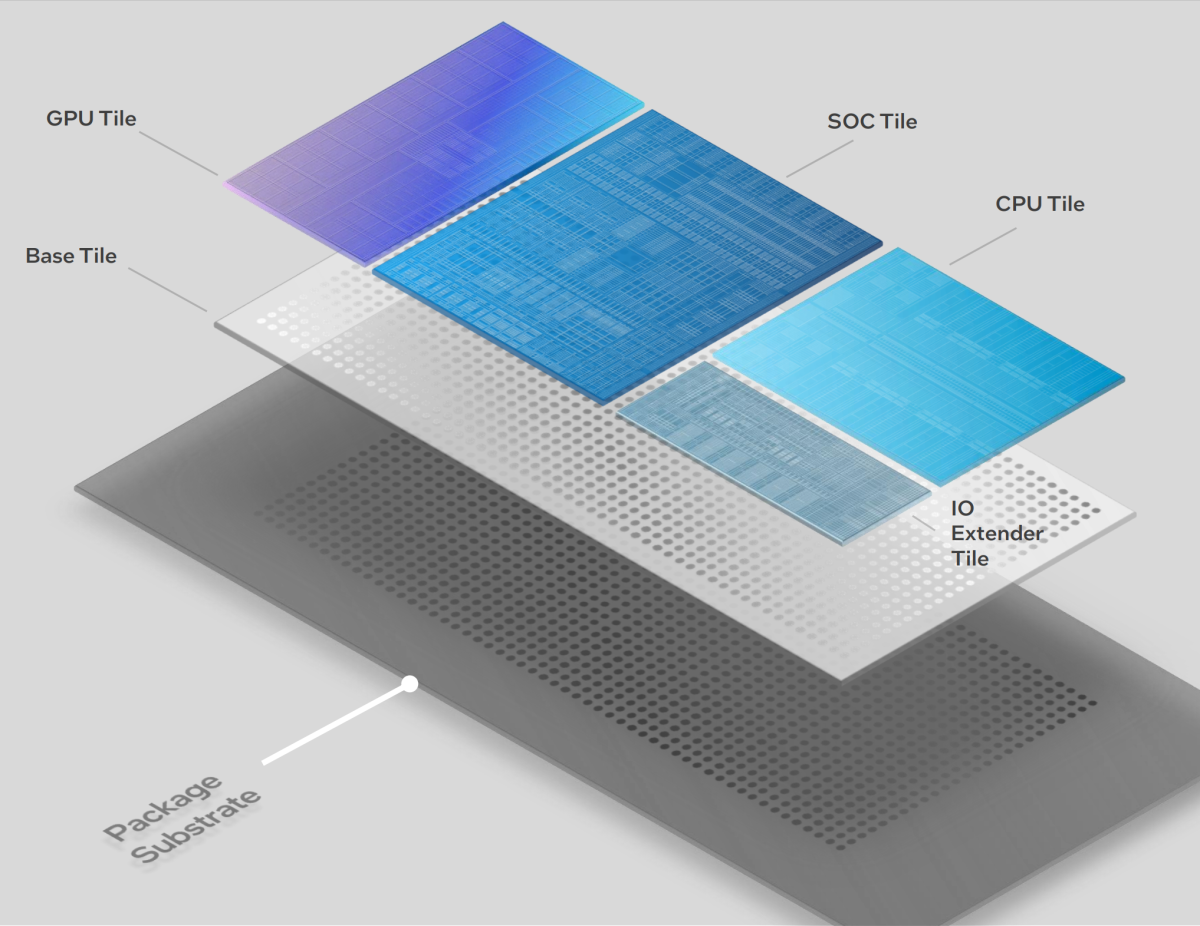

That was the introduction of the Universal Chiplet Interconnect Express (UCIe), and the idea is straightforward sufficient. Use totally different “tiles,” or chiplets, plug them right into a base tile, and join all of them through the UCIe standardized interface to construct the chip of the longer term. It’s fairly straightforward to see this “base tile” as a motherboard of types, with numerous elements hooked up to it: graphics, I/O, and so forth.

What UCIe does is current a really standardized, open interface to permit this to occur. If you’ve adopted the chip business carefully, it’s possible you’ll know that “standards” don’t at all times apply to everybody; that’s why Intel Core-based notebooks have Thunderbolt ports, whereas these powered by AMD’s Ryzen chips embrace USB 4 ports — they’re functionally equal, but totally different. But UCIe is supported by virtually all the key gamers: AMD, Intel, Microsoft, Qualcomm, Arm, Samsung, and TSMC, amongst others. The solely exception, for now, is Nvidia.

Intel has been iterating on chip and chiplet design for many years.

Mark Hachman / IDG

Gelsinger has lobbied arduous for the Chips for America Act, which was signed into regulation earlier this month, offering $52 billion for the American chip business. Last yr, Gelsinger pledged a return to greatness by investing in new fabs and launching Intel’s first foundry enterprise. But Gelsinger stated on the Hot Chips educational convention this week that he doesn’t wish to simply construct fabs for Intel. He needs to construct “systems foundries” for a number of clients, all based mostly on UCIe.

Gelsinger was requested whether or not Intel’s system foundry, and UCIe, would allow a mix-and-match method, the place clients can purchase chiplets from totally different distributors and assemble them collectively. He agreed.

“Yeah, that’s it,” Gelsinger replied. “That’s my expectation, that UCIe becomes like PCIe [PCI Express].”

“We expect UCIe to be the equivalent of that,” Gelsinger added. “You may say, hey, I’m getting two of the chiplets from Intel. I’m getting one of the chiplets coming from a TSMC factory, maybe the power-supply components coming from TI. Maybe there’s an I/O component coming from GlobalFoundries and, of course, Intel has the best 3D packaging technology so they’re going to be the on assembling all those chipset chiplets into the marketplace, but maybe it’s another OSAT [Outsourced Semiconductor Assembly and Test] provider as well.”

Meteor Lake: the subsequent step

We’ve been constructing so far for a while, although the vital work has been carried out within the final 5 years. The most high-profile integration of chiplets from a number of sources was Kaby Lake-G, the 2017 mixture of an Intel Core CPU and AMD’s Radeon GPU.

Two different applied sciences have been important to Intel’s improvement: what it calls EMIB, which extends chiplets alongside a 2D aircraft, and Foveros, which permits chip dies to be vertically stacked, in 3D. In 2019, Intel mixed the 2 into what it calls co-EMIB. There are quite a lot of phrases that get bandied about: disaggregation, tiles, and chiplets. They all imply just about the identical factor: LEGO, however with semiconductors.

We’re going to begin to see extra of this idea come to fruition subsequent yr with Intel’s “Meteor Lake” chip, which Intel detailed at Hot Chips. At the underside is the bundle substrate. Above, there’s the “base tile.” And above these are the varied tiles, particularly the GPU tile, the CPU tile, the SOC tile (media, imaging, and show, basically), and the I/O extender tile (the chipset). Intel CPUs have historically contained two dies inside a single bundle; now, there are basically 4.

Mark Hachman / IDG

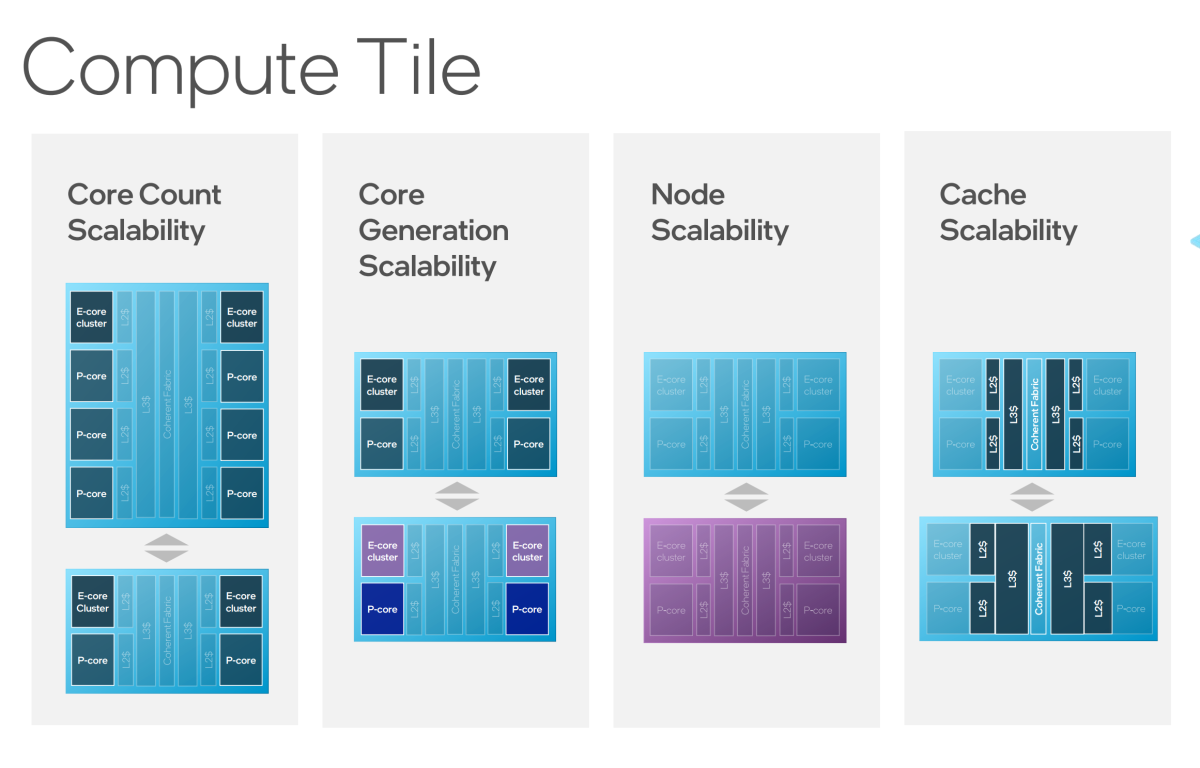

What Intel let slip earlier within the week is that we’re already seeing Gelsinger’s disaggregation imaginative and prescient come to fruition, as most of Meteor Lake’s elements are made by TSMC, not Intel, however shall be assembled into the Meteor Lake chip. At Hot Chips, Intel executives confirmed how every tile may very well be manufactured with variations, resembling a number of preparations of energy and effectivity cores, GPUs with extra processing models, and so forth. It additionally doesn’t matter if some tiles are made on an Intel 4 course of, or a TSMC fab line, or no matter, as they are often dropped in and reused in future processor generations. (Meteor Lake doesn’t use UCIe, nonetheless, because the specification was finalized only a few months in the past.)

We do know that it really works, although. Intel has functioning samples of Meteor Lake, which it has efficiently booted within a PC, executives stated.

Will efficiency endure? Will or not it’s costlier?

That’s a sea change from Intel’s historic stance: construct a single, highly effective “monolithic” chip and stick it in a PC, a server, and (hopefully) a pocket book, too. What was very fascinating is that Intel’s Hot Chips presentation for Meteor Lake (and its successor, Arrow Lake) addressed the query straight. Can Intel get monolithic efficiency with disaggregated structure advantages?

The reply? Intel believes it could actually get shut. There will at all times be a efficiency and energy penalty transferring information from tile to tile, Wilfred Gomes, an Intel fellow in microprocessor design, stated at Hot Chips. But that “disaggregation tax,” in Intel’s view, will solely be about 2 to 3 p.c and outweighed by the pliability disaggregation gives. (Intel didn’t make clear whether or not it was speaking about efficiency, or energy, and what it’s evaluating these numbers to.)

Mark Hachman / IDG

Flexibility impacts your pockets, too. Intel’s objective is to realize chips with a trillion transistors in them by the top of the last decade. But not each chip might be manufactured with out errors. A lithography error, or simply some stray radiation, can basically kill off the complete chip. (Or a part of it — it’s why Intel’s F-series chips lack a functional GPU.) It’s a lot cheaper to toss a hundred-million transistor tile within the trash than a much more costly trillion-transistor monster.

It’s vital to notice that whereas AMD’s Ryzen is transferring forward on chiplets, too (and affords efficiency that competes with and even has outshined Intel’s personal), Intel is taking the lead by way of speaking brazenly about mixing and matching chiplets and tiles. AMD, in contrast, is taking extra of a monolithic method, regardless of Ryzen utilizing a number of chiplets.

The backside line

So what does all of this imply for you? Two issues, principally. For one, the rising complexity and suppleness that Intel’s disaggregation technique allows in chips like Meteor Lake implies that they’ll be more and more arduous to explain; we have already got a mixture of efficiency and effectivity cores, base and turbo clock speeds, built-in graphics cores, and extra in 12th-gen CPUs. Soon, spec sheets may very well be much more dizzying.

The second, although, is extra fascinating, even when it nonetheless feels one thing within the realm of sci-fi, for now. A world during which somebody (an organization? you?) will be capable to order up a chip in a lot the identical method you order a sandwich or a automotive, made to order, is a strong imaginative and prescient. Chip nerds notice that programmable logic and even ASICs have supplied related capabilities for many years. But for the mainstream fanatic, this semi-custom future enabled by UCIe might imply a dramatic rethinking of how your PC’s processor is made.